Product Overview

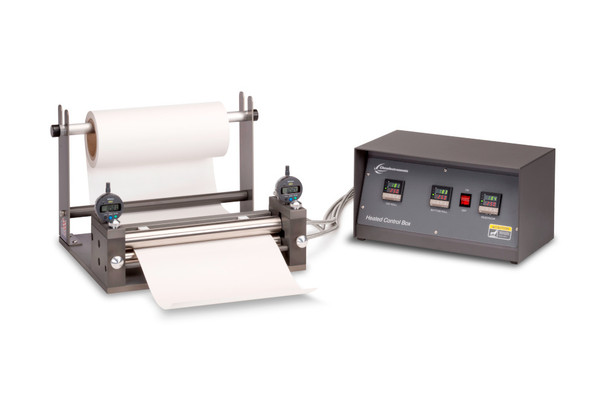

UC-200 Coating head shown with standard unwind stand. The reservoir and side dams have been removed to allow a clear view of the material entering the coating nip. An optional brake unwind for 3” cores is also available.

UC-200 with optional Heated Control Box. The heating elements can be inserted from either side of the coating head, allowing easier use and set up based on your laboratory layout. The Heated Control Box is available in either 110V or 220V versions and can display in either Fahrenheit or Celsius.

- Coating head is designed to be used with or without heating elements.

- Coating bars are interchangeable between top and bottom rolls.

- Comma (Bullnose) bars supplied as standard.

- New coating thickness system allows the top roll to be removed for cleaning while

maintaining set coating thickness. - Dial indicators will be supplied as standard to allow for more repeatable coatings.

- New Dial indicators are digital, replacing the mechanical ones and allowing both metric

and English units (mm and inches). - Will be able to make coatings from 1 mil(25gr/m) to 60 mil(1500gr/m).

- Adjustable Teflon dams allow for coating control from ½” to 12” in width.

- Can be used with emulsion based materials from 1500cps up to 9500cps.

- All aluminum hard coat Teflon construction.

- All hardware is stainless steel.

Accessories

- Bull nose coating bar

- Wire wound coating bars (Mayer)

- Pattern coating inserts

- 3" core chuck with friction brake

- Release paper (roll)

- Polyester (roll)

Options

- Input voltage - 220 VAC (50 Hz)

- Custom widths available

- PSTC and TLMI testing manuals and videos

Specifications

Unwind Stand & Coating Head

Height: 18" (46 cm)

Width: 16" (41 cm)

Depth: 18" (46 cm)

Weight: 42 lbs (19 Kg)

Control Box

Height: 9" (23 cm)

Width: 16" (41 cm)

Depth: 9" (23 cm)

Weight: 17 lbs (8 Kg)

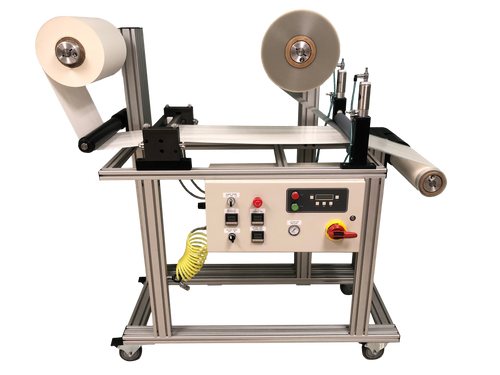

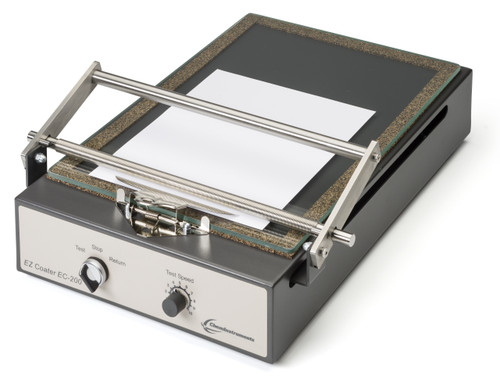

This Knive-Over-Roll (KOR) coating device can be used for the quick and easy application of emulsion and solvent coatings based adhesives. Add the optional Heated Control Box to coat hot melt adhesives. UC-200 Universal Coater creates consistently coated samples from roll stock. The heart of this coater is its two precision ground, 303 stainless steel rolls, which provide a precise knife-over-roll coating method. The Laboratory Drawdown Coater simplifies producing an accurate coating on longer webs for product development or QC applications. Paired with our Benchtop Laboratory Laminator, this coater is the starting point for creating high quality label samples.